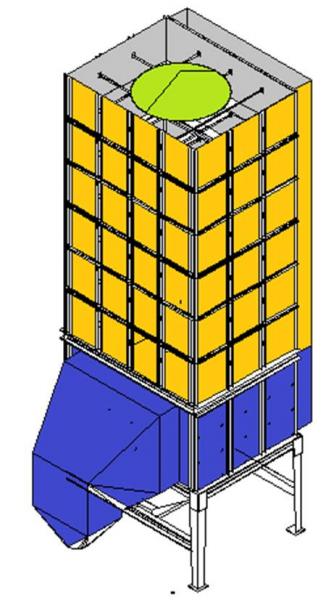

MODULER SQUARE PADDY GRAIN DRYER

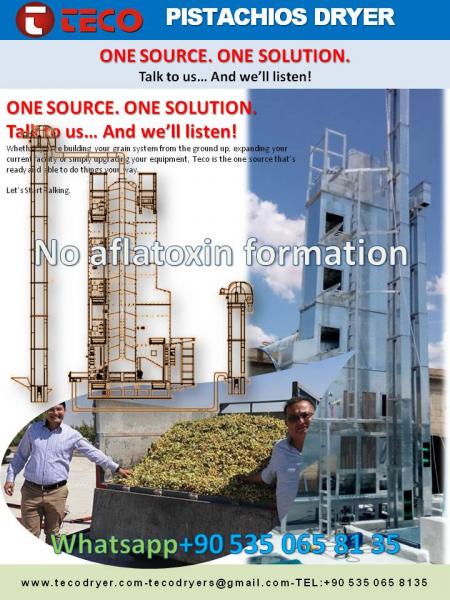

Biomass Grain Dryer

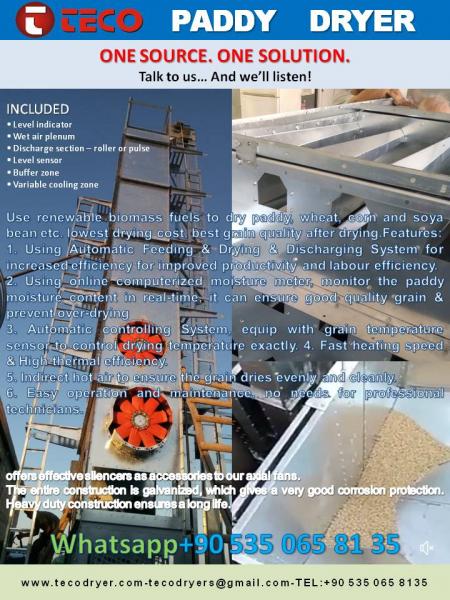

Use renewable biomass fuels to dry paddy, wheat, corn and soya bean etc. lowest drying cost, best grain quality after drying.

Features:

1. Using Automatic Feeding & Drying & Discharging System for increased efficiency for improved productivity and labour efficiency.

2. Using online computerized moisture meter, monitor the paddy moisture content in real-time, it can ensure good quality grain & prevent over-drying

3. Automatic controlling System, equip with grain temperature sensor to control drying temperature exactly.

4. Fast heating speed & High thermal efficiency.

5. Indirect hot air to ensure the grain dries evenly and cleanly.

6. Easy operation and maintenance, no needs for professional technicians.

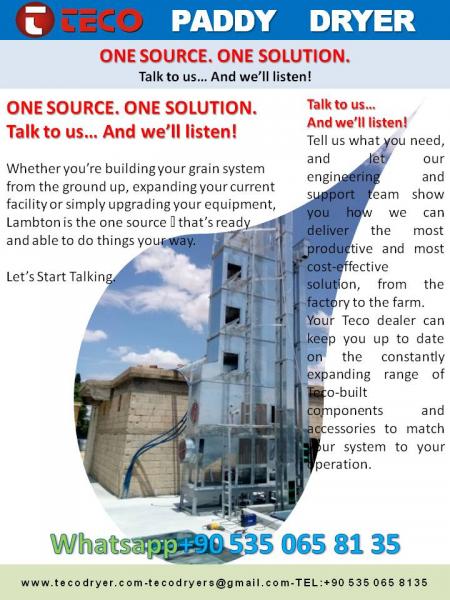

INCLUDED • Level indicator • Wet air plenum • Discharge section – roller or pulse • Level sensor

• Buffer zone • Variable cooling zone

MODULER SQUARE PADDY GRAIN DRYER

Biomass Grain Dryer

Use renewable biomass fuels to dry paddy, wheat, corn and soya bean etc. lowest drying cost, best grain quality after drying.

Features:

1. Using Automatic Feeding & Drying & Discharging System for increased efficiency for improved productivity and labour efficiency.

2. Using online computerized moisture meter, monitor the paddy moisture content in real-time, it can ensure good quality grain & prevent over-drying

3. Automatic controlling System, equip with grain temperature sensor to control drying temperature exactly.

4. Fast heating speed & High thermal efficiency.

5. Indirect hot air to ensure the grain dries evenly and cleanly.

6. Easy operation and maintenance, no needs for professional technicians.

INCLUDED • Level indicator • Wet air plenum • Discharge section – roller or pulse • Level sensor • Buffer zone • Variable cooling zone

supply different sizes of catwalks, ladders and platforms. All parts are made of galvanized steel and are designed for European requirements.

offers effective silencers as accessories to our axial fans.

The entire construction is galvanized, which gives a very good corrosion protection. Heavy duty construction ensures a long life.

Heat

The accurate control of this heating process is what makes the equipment energy efficient. As the ambient

conditions (temperature and relative humidity) change, as well as the desired plenum setpoint, the gas

control system will respond to opening or closing to allow more or less fuel to flow to the burner.

Air

Ambient air is supplied to a fan that is horizontally mounted on the exterior of the dryer which pushes it through a burner to raise its temperature, then forces it across the column of grain.

The function ofthe heated air is to facilitate a heat and mass transfer process. As the heated air passes over the grain, the heat from the air is transferred to the grain thereby elevating the emperature of the grain (heat transfer).

Similarly, as the grain is heated, the moisture of the grain will start to exit to its surroundings as the equilibrium moisture of the grain is reached.

This leads to the transfer of moisture from the grain to the air (mass transfer).

Time

The time element of grain drying refers to the time the grain is spent inside the dryer.

The time that the grain is exposed to the heated air determines how much moisture is driven out of the grain.

The longer the exposure, more moisture removal occurs. As such, the best method for controlling the amount of moisture

removal in the grain is to increase or decrease the grain s retention time by increasing or decreasing the discharge metering speed.

The slower the metering system operates, the longer the grain is exposed to the heated air and the moisture removal is increased.

The faster the metering system operates, the shorter the grain is exposed to the heated air and the moisture removal is decreased.

The easiest way to keep good grain quality and accurate control is to keep heat and air consistent while varying only grain retention time, which has proven to be the most common and efficient way to dry grain.

Drying rate list is for reference only. Actual data will differ by ambient temperature, relative humidity, grain variety, hot air temperature, moisture rate before and after drying.

PlenumThermocouple

The Plenum Thermocouple is a temperature sensing device located in the plenum used to send a signal to the temperature controller to establish and maintain plenumtemperature.

Proximity Switch

The Proximity Switch is used to detect the rotation of the discharge metering system by sensing the proximity of a detector on the discharge metering shaft. If the rotation of the shaft goes undetected for a set duration of time, the machine will be shutdown.

HighVoltageCabinet (Axial Fan Models)

The High Voltage Cabinet contains all of the motor starters and protectors, main power disconnect,programmable logic controller (PLC), breakers, relays, and other associated electrical hardware. The imageshown below is for axial fan equipped models

Pinnacle Lite Remote Cabinet

The Pinnacle Lite Remote Cabinet is where all of the dryer controls are located including the Pinnacle LiteHMI touch screen, power switches and indicator lights, as well as fan, burner, fill and discharge controls.

Pinnacle Lite Remote Cabinet

The Pinnacle Lite Remote Cabinet is where all of the dryer controls are located including the Pinnacle LiteHMI touch screen, power switches and indicator lights, as well as fan, burner, fill and discharge controls.

Illuminated Selector Switch

Illuminated Selector Switches are a combination selector switch and indicator light devicewhich is used to start/stop devices and also indicate that the associated devices are inoperation when looking at the remote cabinet from a distance.

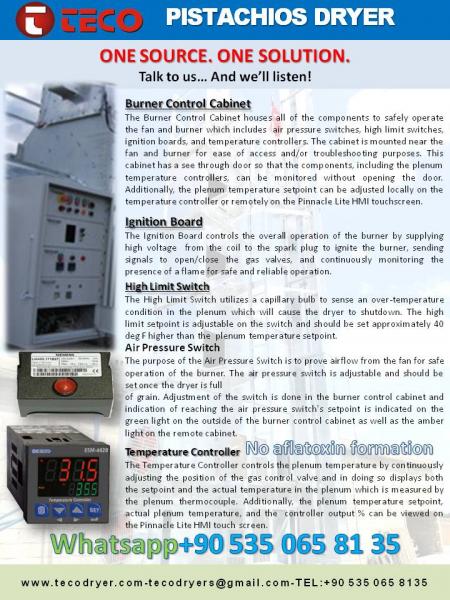

Burner Control Cabinet

The Burner Control Cabinet houses all of the components to safely operate the fan and burner which includes air pressure switches, high limit switches, ignition boards, and temperature controllers.

The cabinet ismounted near the fan and burner for ease of access and/or troubleshooting purposes.

This cabinet has asee through door so that the components, including the plenum temperature controllers, can be monitoredwithout opening the door.

Additionally, the plenum temperature setpoint can be adjusted locally on thetemperature controller or remotely on the Pinnacle Lite HMI touchscreen.

Ignition Board

The Ignition Board controls the overall operation of the burner by supplying high voltage from the coil to the spark plug to ignite the burner, sending signals to open/close thegas valves, and continuously monitoring the presence of a flame for safe and reliableoperation.

High Limit Switch

The High Limit Switch utilizes a capillary bulb to sense an over-temperature condition inthe plenum which will cause the dryer to shutdown.

The high limit setpoint is adjustableon the switch and should be set approximately 40 deg F higher than the plenumtemperaturesetpoint.

AirPressureSwitch

The purpose of the Air Pressure Switch is to prove airflow from the fan for safe operationof the burner.

The air pressure switch is adjustable and should be set once the dryer is full of grain.

Adjustment of the switch is done in the burner control cabinet and indication ofreaching the air pressure switch s setpoint is indicated on the green light on the outsideof the burner control cabinet as well as the amber light on the remote cabinet.

High Limit Switch

The High Limit Switch utilizes a capillary bulb to sense an over-temperature condition inthe plenum which will cause the dryer to shutdown. The high limit setpoint is adjustableon the switch and should be set approximately 40 deg F higher than the plenumtemperaturesetpoint.

AirPressureSwitch

The purpose of the Air Pressure Switch is to prove airflow from the fan for safe operationof the burner. The air pressure switch is adjustable and should be set once the dryer is full

of grain. Adjustment of the switch is done in the burner control cabinet and indication ofreaching the air pressure switch s setpoint is indicated on the green light on the outsideof the burner control cabinet as well as the amber light on the remote cabinet.

TemperatureController

The Temperature Controller controls the plenum temperature by continuously adjustingthe position of the gas control valve and in doing so displays both the setpoint and theactual temperature in the plenum which is measured by the plenum thermocouple.Additionally, the plenum temperature setpoint, actual plenum temperature, and the controller output % can be viewed on the Pinnacle Lite HMI touch screen.

Discharge Limit Switch

The Discharge Limit Switch is a spring loaded lever that maintains a normally open contact which is held closed.

The purpose of this switch is to detect a discharge grain overload condition that may be a result of a failed discharge auger or takeaway equipment. Oncean overload conditions exists, the top door on the discharge auger will lift up and the switch will return to its normally open position; in doing so, the safety circuit is opened and the dryer is shutdown.

GasTrain

The purpose of the gas train is to safely and efficiently supply fuel at the correct pressures and flow ratesto the burners. There are several variations of the gas train depending on what model and options are

equipped on themachine. If the dryer is equipped for LPG fuel, there will be liquid lines sending LPG to the vaporizer and back to the manifold. CE equipped machines will have gas pressure switches to meet local codes. equippedmachines will have valve proving shut-off valves as well as liquid and vapor venting to meet local codes.

Additionally, the centrifugal fan equipped Infinity Series dryers

ControlValve

The Control Valve is a throttling butterfly valve that controls the fuel flow rate to theburner which is precisely positioned by the control valve actuator. The control valve isconnected to the control valve actuator through a mechanical linkage.

Solenoid Valve

The Solenoid Valve is to start and stop the flow of fuel to the burner. The opening/closingactuation of the solenoid valve is monitored and performed by the ignition board.

Pressure Regulator

The Primary purpose of a Pressure Regulator is to continuously control the supplypressure of the fuel to the gas train manifold. There are various sizes and configurationbased on model and configured options, however the primary purpose is athe same

Manual Hand Valve

The purpose of a Manual Hand Valve is to manually open and close various portion of thegastrainformaintenancepurposes.

Burner

The purpose of the burner is to provide heat to the drying air. This heat come from the combustion of thesupplied fuel and takes place in either the Venturi Burner found on the centrifugal fan equipped InfinitySeriesdryers

SparkIgniter

The Spark Igniter receives high voltage current from the ignition board and sparks toprovide direct spark ignition for the burner.

Flame Sense Probe

The Flame Sense Probe detects the presence of the flame and provides positiveconfirmation to the ignition board so that operation of the burner may continue.

#lpinstalacoes #automação #automaçãoindustrial #comandoseletricos #paineiseletricos #paineleletrico #eletrica #eletrecidade #eletricistaresidencial #eletrotecnica #eletricidadepredial #eletricidadeindustrial #comandos #acionamentoselétricos #secadordegrãos #silodegrãos #schneiderelectric #schneider#lpinstalacoes #automação #automaçãoindustrial #comandoseletricos #paineiseletricos #paineleletrico #eletrica #eletrecidade #eletricistaresidencial #eletrotecnica #eletricidadepredial #eletricidadeindustrial #comandos #acionamentoselétricos #secadordegrãos #silodegrãos #schneiderelectric #schneider#CASP #84anos #silos #agronegocio #avicultura #frangodecorte #frango #matrizes #reprodutoras #incubação #suinocultura #piscicultura #bovinocultura #armazenagem #grãos #ração #armazenagemdegrãos #agronacional #Brasil #safra #planosafra #planosafra2020 #planosafra2021 #fornalha #secadordegrãos#CASP #84anos #silos #agronegocio #avicultura #frangodecorte #frango #matrizes #reprodutoras #incubação #suinocultura #piscicultura #bovinocultura #armazenagem #grãos #ração #armazenagemdegrãos #agronacional #Brasil #safra #planosafra #planosafra2020 #planosafra2021 #fornalha #secadordegrãos#agigroup #armazenagemgsi #comilsilos #comilsilosesecadores #consilos #keplerweber #agrobrasil #agroindustria #silocheio #tanquesmetalicos #cereais #planosafra #poscolheita #rural #safrabrasil #sementes #agroconsultoria #armazenagemdegraos #basedesilos #manutençãoindustrial #montagemindustrial #secadordegrãos #campo #agro #fazenda #agricultura #agronomia #agronegocio #agropecuaria #silo#silo #grão #secadordesementes #secadordegrãos #unidadedegraos #unidadedesementes #silos #canalizacao #transportedegrãos #correiastransportadoras #transportedecereais #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita #revisao #presafra #transportadores#silo #grão #secadordesementes #secadordegrãos #unidadedegraos #unidadedesementes #silos #canalizacao #transportedegrãos #correiastransportadoras #transportedecereais #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita@alvoagricolaoficial @gsi_brasil#tratamentodefluentes#postodecombustivel#ete#estacaodetratamentodeesgoto#armazenagemdegraos#armazenamento#armazenagemdegraos #armazenagem #graos #grãos #agro #silo #agronomia #agronegocio #campo #fazenda #construção #engenharia #engenhariacivil #agroincorporadora #silo #grão #unidadedegraos #unidadedesementes #silos #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita #a #o#armazenagemdegraos #armazenagem #graos #grãos #agro #silo #agronomia #agronegocio #campo #fazenda #construção #engenharia #engenhariacivil#ArmazemparaTodos #armazenagemdegraos #soja #milho#agro #agroboy #agronomia #agronegocio #agropecuaria #silo #fabricacaopropria #ração #grãos #armazenagemdegraos #armazenagem #amoraocampo #vidanocampo #colheita #safra #maquinas #equipamentos#tapurah #obra #silos #armazenagemdegraos #engenharia #fazendas #agro #agromt #2021#aprosoja #planosafra #aprosojabrasil #silos #armazenagemdegraos #armazenagem #grãos #agronegocio #agricultura#eurobaseengenharia #obras #construcaocivil #agronegocio #silos #agro #armazenagemdegraos #equipeeurobase #agroindustria #cooperativaintegrada #cooperativaintegrada💚 #cooperativa #cooperativaagricola

#armazenagemdegraos #grãos #agronegocio #agrocampo #produtorrural #agroindustria #agricultura #ObraspeloBrasil #ObraRural #soja #milho #armazenagem #agrocampo #agrobrasil🚜🌱 #agriculturadeprecisão #cooperativa #agriculturainteligente #colheita #peneiras #maquinadelimpeza #MALT #limpezadegraos #armazenamentodegrãos #agro #armazenagemdegraos #poscolheita #agrointer #gestaoindustrial #gestaodeprojetos #automacaoindustrial #montagem #montagemindustrial #instalaçõeselétricas #cooasavi#eurobaseengenharia #obras #construcaocivil #agronegocio #silos #armazenagemdegraos #equipeeurobase@alvoagricolaoficial @gsi_brasil#armazenagemdegraos #armazenagem #graos #grãos #agro #silo #agronomia #agronegocio #campo #fazenda #construção #engenharia #engenhariacivil

#agronegocio #produtorrural #controlefinanceiro #gestaoderiscos #administracaodeempresas #administracaorural #armazensgraneleiros #silos #soja #milho #blindagem #agriculture #agricultura #armazenagemdegraos #gestaorural #gestaofinanceira #fazendas #safra #emprendedorismo #processosgerenciais #gerenciamentodeprocessos #liderança#perozin #perozinindustria #pecuaria #bovinos #gado #agro #agronegocio #equipamentos #metalurgica #secador #armazenagem #armazenagemdegraos#armazenagem#armazenagemdegraos#silocheio#graos#graosbrasil#agronegocio#cerealista#tombador#guaresi#safra#unidadedearmazenamento#obras#obracivil#projetosindustriais#equipamentosagroindustriais

#romapecas #pecas #silos #secadores #agronegócio #armazenagemdegraos #automacaoindustrial #contrucoes #engenharia #sinopmt #matogrosso #soja #milho #graos #agricultor #agroindustria #johndeere #newholland

#silo #grão #secadordesementes #secadordegrãos #unidadedegraos #unidadedesementes #silos #canalizacao #transportedegrãos #correiastransportadoras #transportedecereais #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita

#silo #grão #secadordesementes #secadordegrãos #unidadedegraos #unidadedesementes #silos #canalizacao #transportedegrãos #correiastransportadoras #transportedecereais #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita #silo #grão #secadordesementes #secadordegrãos #unidadedegraos #unidadedesementes #silos #canalizacao #transportedegrãos #correiastransportadoras #transportedecereais #agro #agricultura #farm #vidanocampo #brasil #agroétudo #agroépop #armazenagemdegraos #armazenagemdegrãos #poscolheita #póscolheita#silos #armazenagemdegrãos ##silosdegrãos #silosdegraosesementes #agronegocio #oagronaopara #oagroehtop #eletricidade #energiaeletrica #servicoseletricos #redeseletricas #comandoseletricos #eletricista #quadrosdecomandos #redesdeenergia #transformadoresdeenergia #automacao #eletricidadepredial #eletricidadeindustrial#armazenagemdegrãos#agricultura#soja#milho#silos#oagronaopara#gsibrasil#quemarmazenacresce#soybeans

#silos #armazenagemdegrãos ##silosdegrãos #silosdegraosesementes #agronegocio #oagronaopara #oagroehtop #eletricidade #energiaeletrica #servicoseletricos #redeseletricas #comandoseletricos #eletricista #quadrosdecomandos #redesdeenergia #transformadoresdeenergia #automacao #eletricidadepredial #eletricidadeindustrial

#mısırkurutma #mısırkurutmamakinası #mısır #mısırkurutma #mısırüretimi #yem #arkorhayvancılık #hayvancılık #büyükbaşhayvancılık #mısırtarlası #hayvancılıkmarketi #gıda #tahıl #hasat#çamburnu #sürmene #trabzon #kemerliköyü #karakoz #mısır #mısırkurutma #koliva #patlamışmısır #karadeni̇z #karadenizpaylaşımları#gununkaresi #netgo #turkiyedenkadrajlar #karadeniz #aziz_anadolu #anadoluda_biryer #trtavaz #colors_of_day #ig_turkey #trabzondayiz #trtbelgesel #altinkare #onetrabzon #photo_turkey #turkobjektif #altinvizor #anadolu#objektifimdenyansıyanlar #photo #fotoğraf