Things to Consider Before Buying a Grain Dryer (Indian Context)

1. Drying Capacity (Tonnes per Hour or Day)

-

Always check how many tonnes of grain the dryer can handle per hour or per day.

-

Small farms may need 2–10 tonnes/hour

-

Large farms or agri-businesses may need 30+ tonnes/hour

-

Choose the capacity as per your harvest volume and peak-season needs.

2. Fuel Type and Availability

-

In India, fuel accessibility and cost can vary by region. Common options:

-

Diesel – widely available in rural areas

-

Biomass (husks, firewood) – cheap and eco-friendly

-

Electricity – suitable if you have a stable supply

-

LPG or natural gas – cleaner, but less common in remote villages

-

-

Pick a dryer that supports the most affordable and accessible fuel in your location.

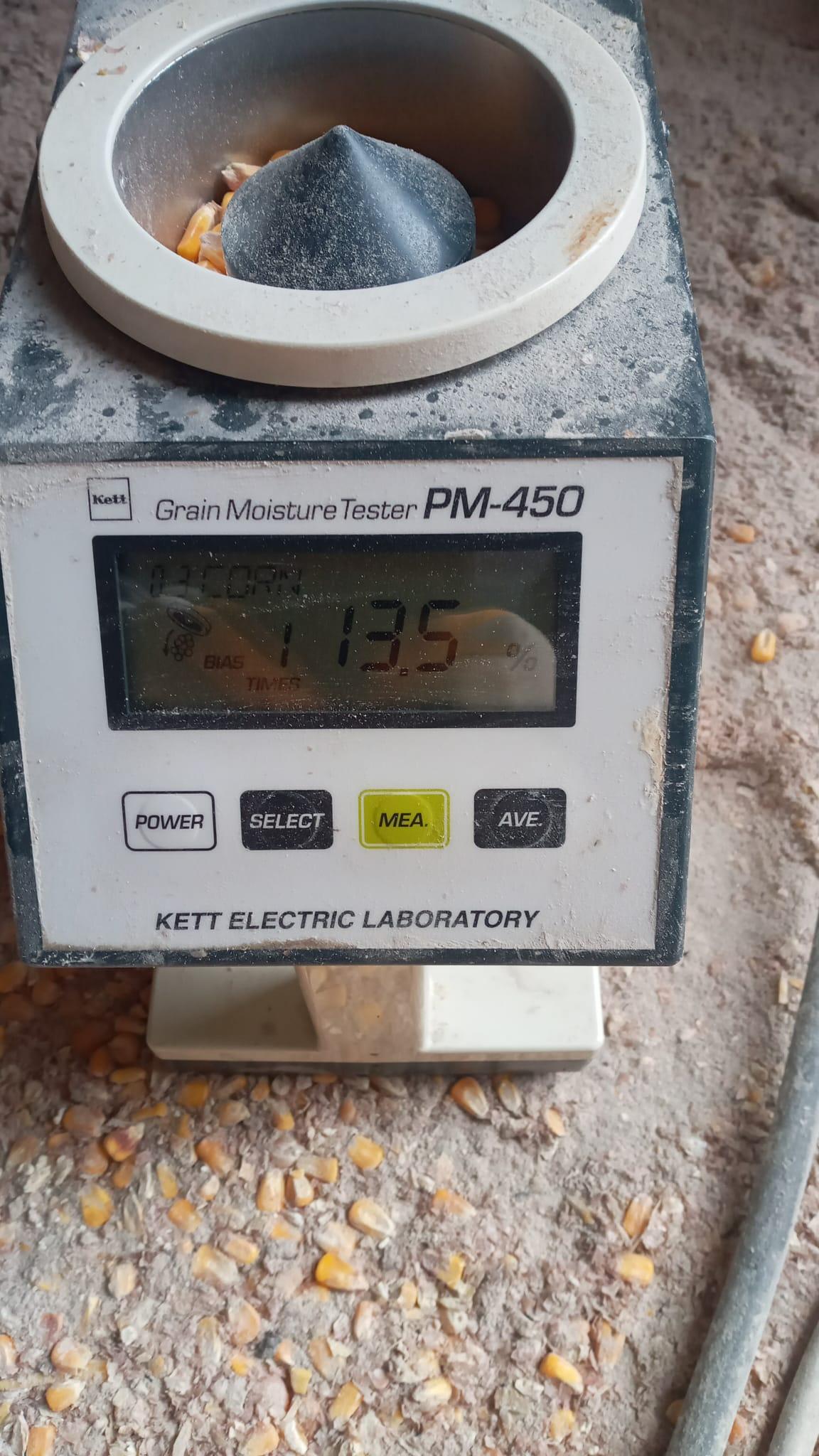

3. Moisture Control and Automation

-

Look for models with:

-

Digital or sensor-based moisture control

-

Auto shutoff after reaching desired moisture level

-

Manual override options

-

-

This ensures safe and consistent drying, reducing risk of spoilage during storage.

4. Uniform Drying

-

Proper airflow and temperature distribution help ensure even drying of grains.

-

Uneven drying may lead to fungus, mould, and quality degradation.

5. Power and Fuel Efficiency

-

Power cuts are common in rural areas, so consider:

-

Low power-consuming models

-

Hybrid systems (diesel + electric, or solar + biomass)

-

-

Better efficiency = lower long-term operational cost.

6. Drying Time

-

Ensure the machine does not dry too fast, which can crack grains, especially in crops like maize or paddy.

-

Ideal dryers allow temperature and speed control based on crop type.

7. Ease of Use and Maintenance

-

Machines should be:

-

Easy to operate, even by semi-skilled workers

-

Simple to clean and maintain

-

Equipped with local language manuals (Hindi, Tamil, Telugu, etc.) if possible

-

-

Availability of after-sales service and spare parts in your region is critical.

8. Mobility (Portable vs. Stationary)

-

Mobile dryers are best for village-level use or shared models.

-

Fixed dryers are good for large farms, processing centres, or mandis.

-

Choose depending on whether you need it for individual use or collective/group farming